近年来公交客流量大幅下滑,整个公交行业都面临着发展困局。部分路线车辆平峰期空驶率高,但是如果降低发车频率,又会导致候车时间过长,公交服务品质下降。针对这一矛盾, “大空间、弹性运载能力”成为了公交技术创新的关键突破点。

Accompanied with the dramatic drop in bus ridership in recent years, the entire bus industry is facing development dilemmas. Buses of certain routes had high empty-loaded rate in off-peak hours, while reduction of departure frequency would lead to overlong waiting time and drop in quality of bus service. To this end, "large space and elastic carrying capacity" has become the key breakthrough point for bus-related technological innovations.

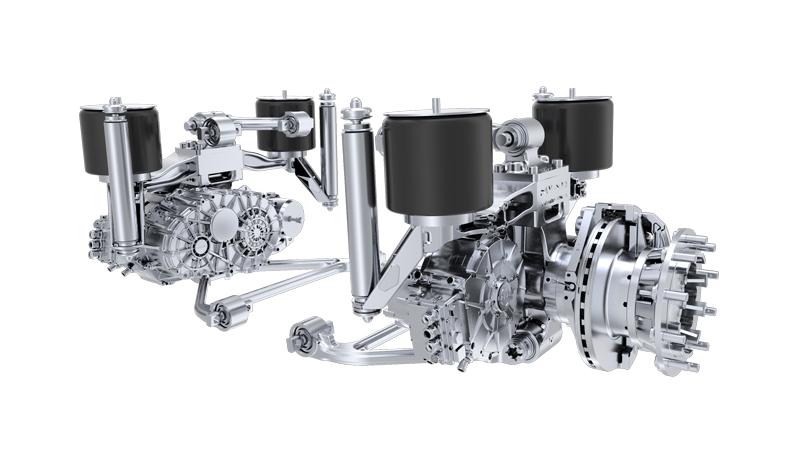

盘毂动力面向新能源公交车领域推出了“地铁巴士”公交运力解决方案,即四气囊独立悬架轮边驱动系统,应用“体积小、重量轻、效率高”的轴向磁通电机替换传统径向磁通电机,采取分布式的驱动方案和独立悬架结构,取消刚性驱动桥、传动轴、主减速器和差速器,减少了传递效率的损失和桥包对车内布局空间的影响。

PanGood Power has introduced "BMT" carrying capacity solution in the field of new energy bus, i.e., wheel-side drive system with four airbags and independent suspensions. It replaced the conventional radial-flux machine with axial flux motor of small size, light weight and high efficiency, used distributed driving solution and independent suspension structure, and removed rigid driving axle, transmission shaft, main reducer and differential, thus reducing loss of transmission efficiency and impact of bridge on interior layout and space.

四气囊独立悬架轮边驱动系统

Wheel-side driving system with four airbags and independent suspensions

这套系统将传统公交车型升级为具有地铁一般“一步登车、全平地板、大通道”特征的新一代低地板城市客车。首先,车辆运载能力有效增强。得益于轮边驱动系统带来的全平地板结构使得整车有效站立面积明显增加,8米的“地铁巴士”公交最大载客能力达到85人,相当于10米传统公交车,10米“地铁巴士”的运力水平则与12米传统车型相当。

This system has upgraded the conventional bus model to a new generation of low floor city bus with metro like features of easy access, full-flat floor and wide aisle. Firstly, bus carrying capacity has been effectively enhanced. Benefited from the full-flat floor comes with wheel-side driving system, effective standing area of the whole bus increased significantly. For example, maximum passenger capacity of 8m "BMT" reaches 85 persons, which's equivalent to that of 10m conventional bus model, and that of 10m "BMT" is equivalent to that of 12m conventional bus model.

10.7m "BMT" 12m conventional bus

Maximum passenger capacity of 96 persons Maximum passenger capacity of 98 persons

新型地铁巴士与传统公交车型结构对比

Structure comparison between new BMT and conventional bus models

其次,凭借盘毂四气囊独立悬架轮边驱动系统的应用,“地铁巴士”具备与传统公交车完全不同的车身结构,给乘客带来本质安全的乘车环境:车辆一级踏步,方便老人、儿童、残疾人等弱势群体一步登车,提高便利性降低安全隐患。

Secondly, PanGood's wheel-side drive system with four airbags and independent suspensions endows the "BMT" with a body structure entirely different from that of conventional bus, creating essentially safe use environment for passengers: the one-step boarding feature of the bus can facilitate easy access of senior citizens, children, the disabled and other vulnerable groups, making bus use more convenient and reducing safety hazards.

最后,整套系统总成高度集成,在提供足够动力输出的同时,省去变速器,传动轴等环节,简化机械传动结构,有效提升车辆传动效率;同时结构的简化有效降低车辆自重,整车轻量化程度更高。在相同运力情况下,“地铁巴士”整车车型更小、重量更轻、能耗更低,可以有效降低运营成本。

At last, assembly of the whole system is highly integrated, at the same time of provision of sufficient power output, transmission, transmission shaft and other parts have been removed for simplified mechanical transmission structure which improves the transmission efficiency of the bus and effectively reduces the weight of the bus, increasing the light-weight degree of the complete vehicle. With the same passenger capacity, "BMT" boasts smaller size, lighter weight and lower energy consumption, which effectively reduce operating cost.

目前“地铁巴士”已被金龙、金旅、海格、中车、中通等国内主流主机厂所应用,公告车型数量达60多款,并在上海、福建、浙江、江苏等全国40多个城市投入实际运营,运行车辆4000多台。“地铁巴士”对于推动节能减排的效果十分明显:在相同运力情况下,采用“地铁巴士”方案,生产端公交车辆可减重2-3吨左右,减少碳足迹4吨左右;运营端车辆每年减少碳排放12万吨左右,运营电耗降低26%-33%左右,按每年运营7万公里计算可节电1.5万度左右,节能减碳的同时实现运营成本的有效优化。通过生产端碳足迹的减少和运营端的节能降碳实现车辆全生命周期更低碳化,对城市交通领域实现碳达峰目标和碳中和愿景具有示范性的长远效应。

By now, "BMT" has been used by King Long, Golden Dragon, Higer, CRRC, Zhongtong and other domestic mainstream OEMs, the number of announced bus models reached more than 60, and over 4,000 such buses have been put into operation in over 40 cities throughout the country, including Shanghai, Fujian, Zhejiang, and Jiangsu. "BMT" plays a significant role in facilitation of energy conservation and emission reduction: on the premise of the same passenger capacity, the use of "BMT" solution can reduce bus weight by around 2-3 tons at production end, and reduce carbon footprint by approximately 4 tons; at operation end, it can reduce carbon emission and operating power consumption by about 120,000 tons and 26%-33% respectively on a yearly basis, and save approximately 15,000 kWh of electricity based on annual operating mileage of 70,000 km, which can realize effective optimization of operating cost while achieving energy conservation and carbon emission reduction. Lower carbon emission of the whole life cycle of vehicle can be realized through reduction of carbon footprint at production end as well as energy conservation and carbon emission reduction at operation end, which has demonstrative long-term effect on the realization of carbon peaking and carbon neutrality goals in the field of urban traffic.